Fluke and Transcat Presents Electrical Safety Measurement Webinar

Curt Geeting | Fluke Sales Engineer

In this webinar, Curt Geeting, Sales Engineer at Fluke, details electrical safety procedures and precautions. Curt prefaces his presentation with a brief discussion about electrical measurement safety risks, causes and preventions. Curt continues speaking about helpful electrical safety check lists to abide by & ends the presentation with a note on test equipment safety.

Nicole: Okay, good afternoon, everyone. Thanks for joining us on our call today. My name is Nicole Quinzi from Transcat, and I'll be your moderator this afternoon. Our webinar topic is Electrical Measurement Safety. It's being presented by Curt Geeting from Fluke. Curt is a Fluke sales engineer who supports eastern Pennsylvania, New Jersey, New York City Metro area, and Central New York State. He has worked in the test equipment industry for 33 years. He is certified as a Level 1 thermographer, as a Level 1 vibration specialist and is the Fluke trainer for the International Brotherhood of Electrical Workers. He has been with Fluke Corporation as a regional sales engineer for 17 years.

We expect the presentation today to last roughly 30-40 minutes, and then we'll answer any questions that have been submitted. During any time of the presentation, you can send questions through the question box to the right in your webinar controls. I also want to mention that this webinar is being recorded. Each of you will receive a follow up email with the link to the recorded webinar and the slides of today's presentation. Now, I'm going to turn the presentation over to Curt.

Fluke Electrical Safety Measurement Webinar: Agenda

Curt: Good afternoon. I appreciate everybody's here today. My name is Curt Geeting. Again, I'm with Fluke Corporation. We're looking to enlighten you folks in the Electrical Measurement Safety. We at Fluke have been doing this for almost 20 years now. And this is a real summary I present to customers within their facilities as well as online.

Risk from Electrocution and Shock Hazards

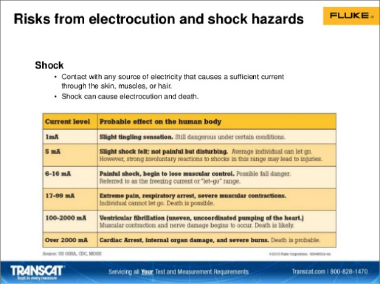

So, we're going to start off with the basic premise. And this is one that I ask customers all the time. Have you ever gotten shocked by anything other than your paycheck? As funny as that sounds, it's not something you're expecting to have happen to you. Certainly, not part of your job description. Your boss doesn't say to you on day five you're going to get shocked. So, we wanted to make sure that everybody is aware of what that has and looks like in terms of the amplitude of the current. So, as you can see from the chart, starting at 1 milliamps, 1/100,000 of an amp all the way up to 2000 milliamps or 2 amps, the electrocution and shock process happens. So, quick the important points to know, at 3-5 milliamps is where the GFCI would trip. And no surprise there. 5 milliamps are where you're going to start to feel the shock. Roughly around 6-16 milliamps and when we see about 10 milliamps, you lose muscle controls through your hands and muscles would lock and spasm.

Hold on to the energized conductors so you could not let go. Obviously after that, respiratory failure starts to occur, so you can't breathe. Or you can't yell out. And somewhere between 100-2000 milliamps, for five seconds across my chest cavity, will stop my heart. So relatively low current, and it is the current not the voltage. So, keep that in mind when you're dealing with circuits that you are both investigating as well as troubleshooting.

So, obviously - whoops - I will go back one slide, my problem. Shock can occur when there's enough current through the skin, the muscles and hair. And then obviously, shock can cause electrocution and death. So again, it's the current, not the voltage, and its relatively low current for those who may not be informed about that. And it doesn't take a whole lot to stop your heart. So, the end lesson there is electricity needs to get respected. Many times, in our industry that is not the case.

Back to Top of Page ↑

Risk from Arc Flash

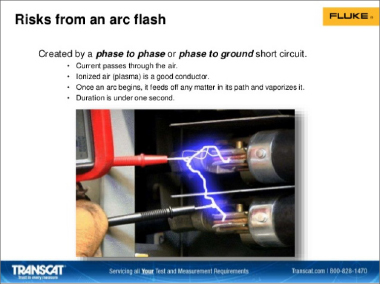

Um, arc flash is the next occurrence that we're going to look out for. And that's basically where you have a connection phase to phase or phase to ground to create a short circuit. Now, the flash portion is a very short duration. And that is an actual flash of light or arcing if you, typical duration under a second. Um, we're showing the example of two test leads that are in very proximity on a higher voltage circuit and obviously, they're arcing over, through the air, through the test leads.

If this arc continues for longer than a second, we have what's called an arc blast. An arch blast is a complete connection of those two phases or a phase to ground and quite a few things are obviously going to happen now. The most intense of which is going to be intense heat and fireball and shock wave coming at the end user. We're going to have blinding light. We're going to have smoke. We're going to have potential be in contact with an energized component. As you can see by that image there, quite a bit of damage. Keeping in mind, obviously, in our industry, this is going to happen with proximity with a piece of test equipment, so the end user is in very proximity to this occurrence when it happens. And unfortunately, that's when many things can occur, even death.

Back to Top of Page ↑

So, we're looking at all the causes. We're going to talk about the first one, what we refer to as transients. So why would an arc flash/arc blast happen? Many times, this is high-speed noise or spikes if you will. That are traveling as well as switching on and off, or if you have utility load switching or it's using things like adjustable speed drives or variable frequency drives as they're known, or lightning strikes. High amplitude, very short duration, and can overcome a piece of equipment or test equipment that does not have the proper input detection and causing an actual arc or shot within the tester itself. So, the amplitude of these can be 8000 volts or higher. This is riding on top of a 480 volt or 240-volt sign wave or wave form if you will, so the amplitudes obviously are extremely high. And very, very fast.

Back to Top of Page ↑

Causes of Transient Incidents

What causes these? Well simply occurrence is where we're moving things. So, I'm racking in a circuit breaker and I might have something touch a live bus or live connection as I'm mocking it in. Loose panel wiring. Somebody didn't do a proper job of tightening a conductor and it shorts out across the space of that left panel or it's ground or it going to have a conductor. Removing panel screws. Things are falling. Meeting live circuit. Hand tools. Very typical, and this is one of the reasons why you should be using insulated tools and obviously insulated gloves. So, if you're - if you're coming across two phases with the end of a screwdriver, obviously, that's going to cause that short. Incorrect test probes are a big one for us. At Fluke, we've seen quite a few of the tips of these blown off. Or misused. So obviously if I’m slipping and I'm on two terminals with a very small barrier between the two, and I accidentally slip and these two test probes cross each other and touch the two phases, I can cross that - that intensity to occur. And then misuse of test equipment. So, the biggest single misapplication we have with - at least I call it near - would be hooking it as an inline series measure as a current measurement and doing it as a voltage measurement across two phases. And we'll get into that a little bit more here in a minute. Testing continuity in a live circuit with a meter that's obviously not designed to handle that and then again accidentally shorting the two phases with the test leads.

Back to Top of Page ↑

Industry Guidelines

So, what we're trying to deal with clients with and I'm sure everyone here on the line is, is what's referred to as NFPA-70E. That's the National Fire Protection Association code 70E. This is an insurance industry standard. And when we're studying the safety standards and specifications for safety-related activities on energized circuits.

Back to Top of Page ↑

Safe Working Distances

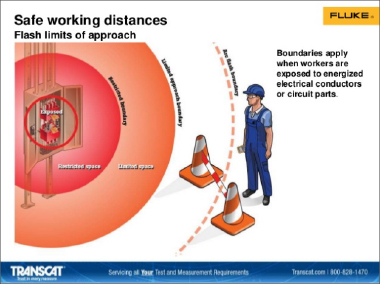

So, with that in mind, part of what gets set forth and what's called safe working distance as a flash limit approaches. And as you can see as the worker approaches, an energized or open panel, the area that - in which he can operate in, without protective clothing is set. So, inside those boundaries, a certain level of PPE or protective clothing must be worn. And outside those boundaries, does not. So most electrical workers, since their using our test equipment and this example of bunch of holding the little tube meter in his hand as you can see, because of the length of the test leads being 4 feet long and most arc flashes being at least 5 feet out, as the nature of being inside of that area, and making those measurements with the use of his hands, would be the considered the inside of that restricted space.

Back to Top of Page ↑

Personal Protective Equipment (PPE)

So, what level of PPE, what level of protective clothing is required? Well the panels would be rated based on the calorie rating and the arc rating and the PPE category required. As you can see we go up in the calorie rating, so do the layers of clothing as well. I mentioned to continue to - along the lines of having face shields, insulated tools, insulated gloves, hearing protection, eye protection, so there's quite a few things that the ending worker must be putting on to be considered in compliance with NFPA-70E would be my PPE required in that area. We at Fluke do not sell PPE gear. This is something that's readily available on the market. And I certainly would love to have a conversation with the folks at Transcat about your needs for protective clothing.

Back to Top of Page ↑

Risk Reduction and using the Right Test Equipment

So, test equipment is and are considered - excuse me more considered part of PPE, our need is to establish to protect you. We have been active at Fluke in getting this due to the standard.

And as you can see, the meter must be rated for:

- The circuit and equipment for which it's connected to

- It must be used in the proper environment

- It should be visually inspected for defect or damage

- And the insulation protective tools including the voltage tester shall be verified by test inspection prior to going into the circuit

So, these also fall under the category of the International Standards for low voltage test equipment. What's low voltage in the marketplace? It's 1000 volts and below. Considered low voltage. And that's the market that we at Fluke are in.

Back to Top of Page ↑

Measurement Category Locations or Ratings

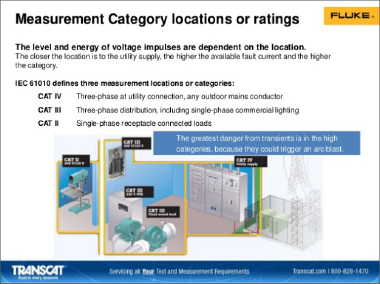

So, we could find this by categorying. And with that we use pictures. Easiest way to describe it is to show where. So, the three categories we're going to talk about, and there's four, but there's three we're going to show here, are:

- CAT III which is three phase at the utility connection and any outdoor mains, so for those folks who are working outside in electrical environments

- This is considered a CAT IV environment. Whether I'm on the roof or I'm outside working on electrical connection, this is CAT IV. CAT III would be my three-phase distribution in the world that most electricians operate in in terms of voltage, amplitude. That would be 208 volts up to 480 volts here in the United States and if you're in Canada that would go all the w ay up to 575. Single phase receptacle loads

- Which is obviously plugging into an outlet, would be considered CAT II and then CAT I which is not shown is the output side of 24 volts or 12-volt DC power supply. So, based on the environment where the need is going to be used, would have to have the right category rating on the face of the meter to show that it's appropriate for that application

Back to Top of Page ↑

Ensuring Test Equipment Standards are Met or Exceeded

So, we at Fluke are trying to do everything we can to meet or exceed those industry standards, and obviously in full compliance with NFPA-70E and IEC 61010, which is the standards for low-voltage test equipment international. And for the most part, again, most electricians are operating at 180 or 600 volt three-phase circuits. So, the typical application - much of the applications fall within that CAT III 600-volt range, but certainly we have a large contingency of customers using these in CAT IV outside environments.

First the Category the Voltage

So, first the category then the voltage. So, we're looking to make sure that the meter can handle the full voltage range of the category you're going to be using it in. Most meters now minimally have a rating of CAT III, 600 volts, considered the minimal acceptable standard by us in most environments. And the higher the category rating, the higher the transient protection in the meter as well. As you can see, a CAT 3000-volt meter can withstand an 8-kV transient. And by the way that’s on every range of the meter, and it is multiple times that we subject the meter to that. And a CAT III 600 volt can withstand a 6 kV or 6000 volts. So, there's a fair amount of over voltage protection now, afforded the end user inside this meter when we have the CAT ratings on them.

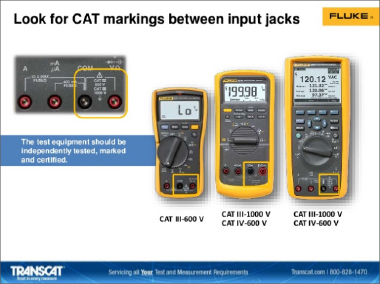

Look for CAT Markings between Input Jacks

What you would be looking for would be the ratings on the input jacks. So, on the multimeter obviously, you are right between the volts in common, as we can see in the exposed view on the left. If it's a clamp on it might be at the bottom of the meter, but they need to have markings there, none the same. So, since the standard started in 1997, we at Fluke have been putting Category ratings on our meters since that point. We started making meters in 1948, so we've been at this for 68 years, now, and obviously made quite a few meters as did everybody else, prior to the standards coming into play.

So, what does that mean? It means that the favorite old Fluke 77 that you bought back when it came out in the late '70s or early '80s is still serving you well. It's a great meter, don't throw it away. Keep that handy, but you're not allowed to use that at work anymore, because it doesn't meet and it is not in compliance with an NFPA-70E. Again, there is no Cat rating on it. Or in the case of an older 70s series 3 meter at the right, it's CAT II-600 V, and again the minimum accepted rating now is CAT III-600 V. That's what - that's what is considered in compliance as a minimum acceptable rating. Okay?

Independent Testing and Certification

So, the other part that we're looking for and that you should be looking for as an end user, is the third-party safety rating. And we deal with three different safety agencies, because we sell the products worldwide. So, you all here in the United States, CSA and Canada and then TUV in Europe. And some meters have multiple safety ratings depending on what areas of the world that we're selling them in. But minimally you should have at least one, and the idea there is that it's not just us saying that we meet the standard, but we are listed to - not just assigned to - a standard. So, it's been tested as a developed product by a third-party safety lab. This is your assurance the meter meets or exceeds the standards.

Read and Understand the Manufacturer’s Instructions

Obviously, the customers do get a manual. Whether they read them. We're not too sure. But our manuals are available for the products, and all manuals are available from the Fluke - to be able to be downloaded from Fluke.com website. Please do refer to that for any safety instructions so that everybody is clear that this is not the complete safety training. Please read and understand the manual that came with your meter.

Back to Top of Page ↑

Non-Contact Voltage Detectors

Non-contact voltage detectors are interesting. We sell a lot of these. It's a quick verification tool. It beeps and/or lights up and or combination thereof when there's the presence of voltage. They are certainly used as the first line detector. It is used to test the absence of voltage, which is many times what people are using meters and clamp meters for. But still one needs to put PPE gear on and the meter still needs to have a category rating, which they all do, and again minimally CAT III 600 V. So, you're not physically contacting circuit. Only coming into proximity of it. I still need to make sure that the meter is properly rated and I'm using it the same way I would use any of the test equipment.

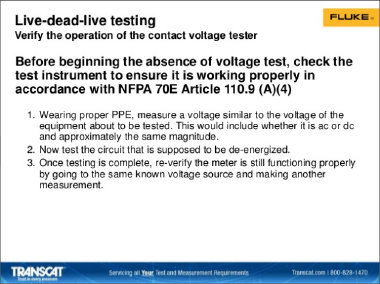

Verifying the Operation of the Contact Voltage Tester

So, the sequence for testing looks like this. You should be finding a live circuit associated or close by that I could test and verify the operation of my meter. Go into the target circuit, which we're assuming are de-energized and are looking - sure that it is dead or de-energized. And then we go back to the live circuit again. So, it's the three-point method by which to verify my contact or non-contact voltage tester is in fact working. The idea is obviously I'm trying to have 100% confidence that, that circuit is in fact de-energized. And this is the easiest way to figure that out and know that my meter is working and telling me the truth.

Optional Readiness Test

So, we have many customers now that are telling us, I don't have a reference circuit. I'm operating on switch gear cabinet, or I'm outside at a transformer. So, what we've launched at Fluke is a new product here in the last year called a PRV 240. This is a little, handheld reference source that also operates and has the ability of producing 240 volts AC/DC to verify the operation of any meter prior to going into a known circuit - or unknown circuit I should say. And if you're interested the folks at Transcat can certainly talk to you about this. And if there's an interest in getting specifications on these and possibly wishing to obtain one of these, they can certainly help you out with that as well. But that's why we released the product, because we do have customers that have no ability to verify against the non-circuit. There's nothing in the immediate area that they can test the meter against.

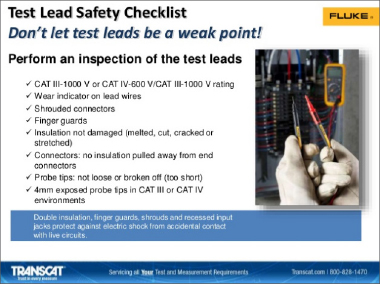

Test Leads Safety Checklist

Test leads are a big source of weakness. They are probably the weakest link in any multi-meter current meter system. We see a lot of folks wrapping their leads around their meter. I see that quite a bit. And we're not doing them any favors when we do that. Right? Keep pulling on the leads in any direction and wrapping them around your meter tightly, you're basically going to be breaking the small conductors inside those wires. So, we're ensuring that they have the proper rating. We're ensuring that they have a shrouded connectors and finger guards for making sure that they're not melted. That the insulator is not pulled away. That the probe tip is not loose or broken off or blown off. And we're going to make sure that the - they're used in the proper environments for which they're designed. What we're very big on at Fluke is the idea of testing your leads as well as your meter. And we'll get into that a little bit.

Back to Top of Page ↑

Minimize Exposed Metal for Safety

So, minimize exposed metal. So, most test leads basically have 3/4 of an inch to possibly an inch worth of metal tip hanging out at the end of the lead. What we've come up with at Fluke is a set of leads called TL-175. These are the left of the picture to the right. They're called safety leads. And the idea is you can twist them to have an external shroud surround the top of the meter, as is evidenced by that red probe. When I'm in very tight environments and I'm trying to minimize the exposed length of the test probe. And then those environments where it's okay to have extra length. I can twist it back and have it exposed back. So, both the red and the black probe will both extend in both directions. And allowing us the additional protection if you've been drinking too much coffee and have a shaky hand and you slip on a circuit. I don't have very much probe tip, so I can't possibly short two of these out together at the same time.

So, the bottom line is safety first:

- Lock out/tag out.

- Work on de-energized circuits.

- Wear all the protective clothing.

- Don't work alone. If you can at all help it.

- And practice safe technique of connecting the ground lead first and the hot second.

- Disconnect the hot lead first and the grounded second.

- And doing a three-point test method.

- Doing testing against no known live circuit. A dead or supposedly dead circuit. And then the last circuit. To verify two things:

- My meter is working and

- That circuit is in fact dead.

That will give you the 100% confidence that you can go ahead and work in that de-energized circuit.

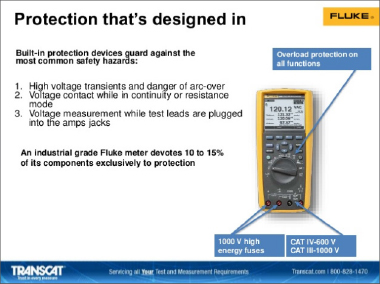

So, we put a lot of protection in the meters. Obviously as you can see, we put 10-15% exclusively for protection, so that's quite a bit meter and then multiplying by that amount you get the idea of how much front-level protection is built into the product and it is for you the end user that we're doing this. We do not want you to have an accident. We do not want you to get hurt while you're working in that environment, and we're putting every level of protection in the meter to protect you the end user. So, if there is an accident or misapplication of the meter, the meter takes the hit and the end user walks away. That is the thought and that is the design of the meter, but of course we can't help people from doing things that they shouldn't be doing.

Back to Top of Page ↑

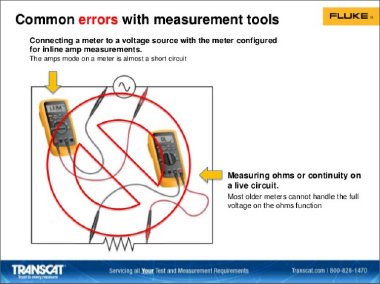

Common Measurement Tool Errors

So how is this application in the errors? These are very typical ones, and we see quite a bit of this. So, the first one is I am hooking my meter into the on the left corner, as a series connection. I have my hot lead in the amp jack with the milliamp jack and the black of the common lead in my common jack and I'm hooked in - across in a parallel way across two phases of AC. This could be something as simple as looking at the neutral and the hot on an outlet. But I'm basically hooked in series, so I'm causing a dead short here within the meter itself.

The second way is illustrated at the bottom is measuring Ohms or continuity on a live circuit. So, I was in what I thought was a de-energized circuit. I have my meter and Ohms and now I'm seeing voltage dropping into the meter. We don't have any issues with that today in any of the products there that we now have CAT III ratings because of the over voltage protection, but in the older meters and particularly older analog VLMs this was problematic, because they were not designed for that, and then many instances that would cause a bit of an exposure. Sometimes taking a portion of the meter out or the entire meter out and putting the end user at risk. So, these are typical misapplications we see on meters these days. And the protection factor recorded in the meter is not allowing for this, to a certain degree.

Handheld Test Tool Safety

We have, however, issues where folks do not use the original fuse that was designed and supplied with the meter. And this is typical application. These are not computer enhanced images. These are actual images from a service lab at Fluke. Somebody decided to put in older, glass automotive fuse into the slot where the original fuse was supposed to be and obviously when called up on to be a fuse, on an AC application, did not perform as such, and there was an explosion.

On the second occurrence, there was a lower rated fuse for 600 V or 1000 V rather than 250 and it didn't open in time and unfortunately, again, this person used the wrong meter on the wrong circuit and/or with the wrong fuse, or combination thereof, and unfortunately did not escape unharmed. He clearly - or she - was not wearing protective gloves and their fingertips burned to the plastic probes and they weren't burnt.

So very common misapplication of a piece of test equipment can result in not just electrocution, but severe upwards of third-degree burns on the hands and on the arms because think about the concept of the meter I'm holding the leads right up to the circuit itself. So, I am right there in that restricted zone.

Protection Devices Provide Additional Safety

So, we put high energy tubes in the meters now. We've been doing this for quite a few years. These are designed for fault up to 10,000 amps in a very short amount of time, and interrupt by default if I've mis-wired my meter and that fuse will open and stop that arc blast. So, we're very particular about this. We do supply these and these are the standard fuses that must be supplied into the meter if you would take out a fuse. You are highly suggested if not required to go to your Fluke distributor in this case Transcat, and buy our replacement fuses. Not all fuses are created the same. And not all fuses are created equally and then not tested. These are tested and rated UL rated fuses. And can again interrupt up to 10,000 amps of live current.

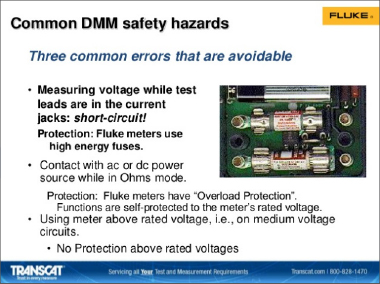

Common DMM Safety Hazards

So, the common misapplications and short circuit hooked into the current jacks all measuring voltage phase to phase. Fuses are protected. Meeting AC or DC power while on Ohms or continuity, and again the ability to protect it up to the full rating of the meter, 600 or 1000 volts including on the category rating and the voltage rating. But not using it beyond that. So, none of our test equipment at Fluke is designed to be used measuring energized circuits beyond 1000 volts. Or 600 volts. So obviously, I'm not going to hook to the primary side of the transformer. For those who are doing inline current measurements, many times we - we find where they have been when they were originally wired for applications for 4-20 mA process loop. And so, that demands shutting down the loop, wiring the meter in series, turning it back on and making our measurement. So, that's why the leads would be there, many times. And the end user would forget that he left those 20-mA common jack and then take the switch position on that vial and put it to mA to volts AC at the 9 o'clock position and then take the lead and measure that same input and the power supply on 120 volts and then pop the fuse and/or the breaker and/or cause the possibility of an explosion to occur. So, that's many times how that happens.

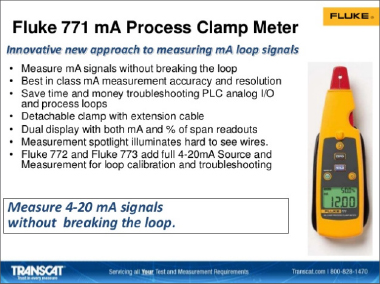

So, we have Fluke have designed a product for this very application called a 771 mA Process Clamp Meter. And the idea is rather than how to break the circuit and allowing ourselves in series, how about the idea that I can take the shielded twisted pair of wires, pick them apart, and grab on to one of those two wires with a very small clamp on and measure current all the way down to 10 microamps. So, we can do a 420-mA measurement without having to break the loop. And, avoid that whole potential of applying my meter to that and blowing the circuit and/or blowing the fuse or pretty ourselves in harm's way. So, that again is the product. And you can talk to the folks at Transcat about. It's a very, very popular product. We've got several 772 and 773 also, output and/or current signal as well.

DMM Safety Inspection

So, using a mode meter and the Ammeter modes, obviously requires, if I did that, I'm probably going to need more fuse. So, the way to test that is you can:

- Take one test lead

- Put your meter in the Ohms position, 12 o'clock dial, on most of the meters

- And take one test lead and jumper from the volts Ohm slot right over to the amp slot or take your probe tip and put it down there

- And we're going to read the resistance of the fuse

- If the fuse is good, there's a resistance

If the fuse is blown there will be an open, and it will show it as an OL. So, that's how we can do that.

So, again, what we're looking for is the idea of working within the boundaries that are acceptable. Making sure that we have the proper PPE on. Making sure that we are operating safely.

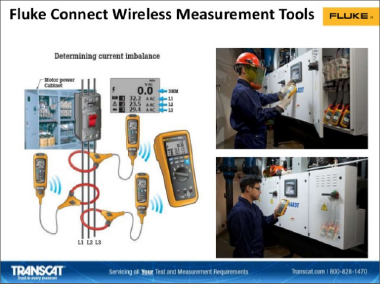

What we at Fluke have been busy doing in the interim in the last three years, is sponsoring several wireless tools that eliminate this altogether. So, the idea is what if I could take my meter and put it on the side of that panel and either take the display off and read it from outside the circuit with the meter mounted inside the panel door. So, I could get to take off my PPE or potentially get to take my PPE gear off.

Back to Top of Page ↑

DMM Selection Guide: Transcat.com/calibration-resources/selection-guides/fluke-dmm/

New Wireless Measurement Tools

And then the other way is to use it with the mobile device. What we call Fluke Connect Enabled. So, we have now started to put an FC - as in Fluke Connect - label on all the new meters that are coming out that are either Bluetooth and/or wireless that will work with Fluke Connect. This is a free application. It's on both the Apple as well as the droid websites. And it's also on Google Play and you talk to that device from a distance of - typically up to 65 feet away. It can talk through the panel door. Gets myself out of the arc flash zone. Allows me to take off my PPE gear. And operating in my normal work clothes or street clothes. And puts me in a very safe environment. And out of harm's way so to speak. So, the typical example of the gentleman who has a panel to work with the three plant meters. And he's talking to it with a multi-meter called a 3000 FC which is a device that will talk to other portable modules. We offer voltage and current modules specific to one task. And they can report out to either multi-meter to either Fluke Connect application which is operating on my mobile device.

But in addition to that, we have been doing this in quite a few other products. And one of the big applications we hear customers want to do, and then we look at all three voltages and all three currents at the same time, simultaneously. I'd love to do it without having to have all my PPE gear on. I'd love to do it on the other side of the panel door. And I'd like to do it through my mobile device like my phone. And to that my response was a model 1736 and 1738. These have been on the market for about a year now, and very popular. They are allowing me to record and run off the circuit itself. So, the beauty of that is - I can power the instrument across any two phases and I don't have to worry about an extension cord and I don't have to worry about leaving the panel door hanging open with that extension cord hanging up there. But rather having the panel run off the circuit itself and we can do that for three months of recording time.

Fluke Connect Overview

So, Fluke Connect is an application. It is free. It allows you, the end user, to record. can share live - to be able to document and to be able to trend your measurements over time wirelessly and paperlessly. And it is all patented by Fluke. And right now, today, we have 36 devices that will work on Fluke Connect. In 2017 we're going to have 100 different meters of all different types that will work with this application. And we can talk to 10 different devices at the same time.

So, it allows the end user a lot of flexibility in terms of where and how they make their measurements. Allows you to operate outside the arc flash zone and lock out/tag out the circuit so the end user standing on the other side of that panel, safely, and makes these measurements. And you'll find this a great way to either start doing it predictively with this program. And to start to document all those readings that you're taking down by hand. So, we can see electrical, temperature, power and energy, thermal images, vibration tools, overall have this capability in them now.

The Safest Way to Measure Electricity

So, the thermal piece is the last portion I wanted to talk about. So thermally it's a great idea to go measure from a distance. Um, so thermal images allows us to do that. Allows us to see the electrical heat or overheated components or overheated transformer all without having to be right next to it.

And so, the idea that I can shoot from some distance away - anybody can take a picture. You can get an idea of what heat content is. And see if it's operating within the manufacturer's acceptable boundaries or not. And, download the data and create reports. For a lot of customers, the idea of seeing the images as a visible display. So, I can see the heat content of why that breaker on the leading to the right of the picture to the right - one from the right - is overheating and tripping. Or why my three-phase motor is stopping and overheating and my drive is tripping or any number of occurrences might be happening as a function of overloaded circuits that are showing as an increase in temperature.

Infrared (IR) Windows for Safety

The safe way to do this are use of what are called IR - or infrared windows. And an infrared window reports to me the ability of monitoring a permanent window, which is pure crystal window, arc flash rated to 63 K and we are good up to 72,000 volts. Mount that on the panel permanently with the peephole if you will and you have a cover that can be flipped down or pulled to the side or can stand outside the panel and shoot through that window and see those thermal and visible lights. And do it from a safe distance, again, without having to put all the PPE gear on and without having to open that panel door every time. So, we lock the window, keep the panel door shut, and look inside that enclosure as a way of keeping you outside the arc flash zone.

Back to Top of Page ↑

Selection Guide: Transcat.com/calibration-resources/selection-guides/fluke-thermal-imager/

Test Instrument Training and Proficiency

So, last thing I want to touch on is being trained. So, under NFPA-70E your employees are supposed to:

- Be trained to select appropriate equipment for the task.

- Demonstrate how they're able to use it.

- Interpret the results.

- Understand the ratings.

- Perform a visual inspection.

- And perform operational verification on a known voltage source.

So, we at Fluke can do this with you two ways. Obviously, we're giving you an overview of how you do this, but we would love to get an invitation from you folks if you'd like us to do this as an onsite explanation of safety class for your entire crew. We can come onsite and do that with our Transcat being our partner to arrange that. With the sales engineers and there's quite a few of us across the country, that do this on a regular basis as a value-added service. So, let Nicole at Transcat know that. They're going to be sending out a survey form, and a feedback form, and if that's your desire, we'd love to hear back from you.

Back to Top of Page ↑

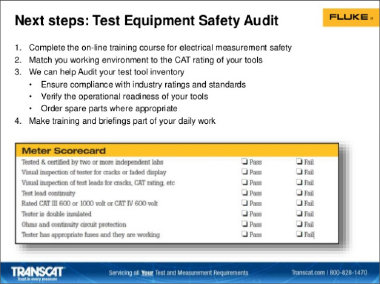

Test Equipment Safety Audit

And with that in mind, we'll leave you one last item. What we call a Test Equipment Safety Audit. What this really, basically is a way of giving yourself a scorecard on your meters, how they invoke the science with NFPA-70E again. Here's all the categories you need to test it across or look at it. We do have an audit sheet, as well, that we can send out to you to help you do this. Called a Safety Audit. It's on a self-template. And something is going to be offered up to you as well, if you would like to do the entire list of all the equipment we have, and do it in one shot. We can help you with that, figure out whether you're in compliance or out of compliance. And all the test equipment that you currently own. So, anything that gets involved with an energized circuit must have the proper ratings on it. Any type of equipment at all that's used as a measurement or testing device. So, that includes quite a few different categories.

So, I appreciate the time today. And hopefully this is informative. And worth your time. And we're looking for opportunities to continue the conversations with you through Transcat. I appreciate your time here today to listen through. And hopefully we created some insight and some value for you here today. We look forward to talking with you folks again, soon.

Nicole: Thank you, Curt. If you'd go to the next slide, um, I'm going to open it up to questions. But if you go to the next slide, there is a promotion. I just wanted to make everyone aware of. Right now, there's a limited time offer. If you buy any Fluke item over $250 you qualify for a gift. Um, of various tools and other items. [CROSSTALK] Curt.

Curt: Yep. And [CROSSTALK] you can download this - I'm sorry.

Nicole: I'm sorry, Curt, we lost you. So, let me just - let me just finish. Um, so this is with purchases for valued up to $1350 and if you go to Transcat.com/deals, you can get the full details and redemption information. And Curt if you'd go one more slide for me.

Thank you. So, everyone we're going to send out a copy of the presentation and the recorded webinar, but my contact information is here if you have any questions or would like to talk to us about any of Fluke interests. In the meantime, I'm going to go to the questions.

Back to Top of Page ↑

Questions and Answers

1. Will you be sharing copies of the presentation? ➩

2. What does NFPA-70E stand for? And why is it important? ➩

3. Can I get a certificate - a CEC - for this webinar? ➩

4. Is NFPA-70E the safety standard for the Canadian market? ➩

5. What are the four category ratings for electrical meters and what do they mean? ➩

1. Will you be sharing copies of the presentation?

Yes, we're sharing copies of the presentation. Um, we'll be sending that in the next few days.

Back to All Q&As ↑

2. What does NFPA-70E stand for? And why is it important?

Oh, yeah. I'm sorry. Yeah. National Fire Protection Association - so this is their safety standard that's been adopted, the de facto standard that the insurance industry is now using in the commercial and industrial marketplace. The importance of that is they're making customers who are operating their own electrical connections and they're responsible for their own electrical distribution to be able to conform in a safe manner. So, there's quite a few rules and regulations around the use of not only test equipment, but PPE, and a variety of other things. And there's one of the - the metrics that customers are getting just by when their insurance company is setting their premiums where you have a large congregation of people - I use a hospital as an example - the insurance industry is concerned about fires running through the walls of the building. And how fast can you move people out of that building? So, they're - they're trying to limit their amount of liability and getting you, the end user, to operate in a much safer manner to eliminate the possibility of explosions and fires.

Back to All Q&As ↑

3. Can I get a certificate - a CEC - for this webinar?

Yeah, um, CEUs or CED's or however you refer to them, are certified educational units or degrees. Unfortunately, no, we do have folks that are offering classes like this that are offering credits for those classes, but we at Fluke are not. So, I apologize, but the content is still more than worthy of knowing and understanding because if you were to go into a class, such as this, that you pay for, it's a lot of the same content. So, understanding it ahead of time before you take a class and get a CED or CEU, you're going to be ahead of the game.

Back to All Q&As ↑

4. Is NFPA-70E the safety standard for the Canadian market?

Um, I'm not sure. I'm not sure if they have the same standard up there or not. I know it's for the U.S. Market, but they may have something equivalent to that. Nicole if you'd like I can get a hold of Eddie Tzonka who is my counterpart up in Montreal.

Back to All Q&As ↑

5. What are the four category ratings for electrical meters and what do they mean?

Okay, so the four ratings, again, were CAT IV, CAT III, CAT II and then I verbally described CAT I as it's shown. So, these are the environments in which the meter is going to be used. The physical environment. Whether you used - they're used outside? Are they used inside? And what amplitude of voltage is the meter going to be exposed to? As a way of verifying that you've got the proper meter for the proper application.

Back to All Q&As ↑

6. How's the level of PPE required to be worn by the person using the meter in a live circuit determined?

Okay, so that's determined, again, through NFPA-70E as categories 1, 2, 3 and 4. Which was on one of the slides I showed earlier. And calls out the level of PPE and the calorie rating. Calorie rating on the clothing and the level of number of layers of clothing that must be worn. So, it is called out [CROSSTALK]. It's called out in an NFPA-70E under PPE.

Back to All Q&As ↑

7. What are the three actions a meter user needs to take every time they use the meter? Before going into a live circuit and determine it to be de-energized or safe to work in?

Okay, so the three actions are doing a continuity measurement resistance measurement in my test leads to make sure that they're not poking. That they're working. To be able to test my fuse as was illustrated in one of the slides to make sure that that is a test by the meter that the fuse is in fact working. And then you do three-point test method of live, dead, live. So again, we're going to a known live circuit or it's not available, using something on the lines of Fluke PRV-240 proving units, as testing against a known live circuit and then going on to the target circuit, which is at this point been de-energized, verifying that it's de-energized or dead. And then going back to the known live circuit again. So, we're testing leads. We're testing fuse, doing a live/dead/live test verification with the use of our meter.

Back to All Q&As ↑

8. Where and what are the three margins on the meter to signify that the meter is properly rated for the environment where it's going to be used?

So, from the call we were talking about the category ratings, and the location of these would be next to the volts and common connections on the face of the meter. If it's something like a clamp meter, it might be in the bottom - the lead plug in on the bottom. You might see them there. But again, a minimum acceptable rating is CAT III 600 V. If you're going to be using it outside, it would be a CAT IV rating. There's two different rating levels - there's 600 V and 1000 V and on the back of the meter is the third-party safety agency rating. So, it will either have UL, CSA or TUV as a third-party safety agency that has listed the meter and proved the meter.

Back to All Q&As ↑

Nicole: Okay. Um, there's one question that I'm going to just have you answer privately. So, that's about it for our questions. So, I'm going to vacate our time for today. If anyone has further questions, or would like to find out more about our product offerings, please contact 800-800-5001, or on the web at Transcat.com. Or you can email me directly. My information is on the last slide, but it's Nvanwert@Transcat.com. Thank you for joining us today. We hope you got something out of the presentation, and that you continue to join us for future Transcat e-learning webinars. Thank you, Curt.

All right. Thank you. Bye now.

Thanks, Everyone.

Have more questions? Contact Transcat today!