Robotics Manufacturing Calibration Services

The manufacturing of industrial robotic systems requires accuracy, precision, and safety in the construction of the robots, but also in the installation, use, and maintenance by the manufacturers’ customers. As a result, robotics manufacturers are subject to industry-specific guidelines such as ISO 10218 and ANSI/RIA R15.06. These guidelines recognize the variable nature of hazards in thousands of applications of robotic systems.

Transcat accredited tool calibration services for test and measurement instruments helps robotics manufacturers and their customers maintain optimal performance and adherence to safety standards throughout the lifecycle of their robotic systems.

Manufacturing and Assembly of Robotic Systems

Manufacturing industrial robotics involves expertise from multiple disciplines, including mechanical engineering, electrical engineering, computer science, and robotics. Transcat Calibration Service experts can calibrate a wide range of instruments across these disciplines to enable your technicians including:

- Machining

Tool calibration is important to maintain precision in milling, turning, drilling, and grinding to shape metal, plastic, and composite parts. Transcat calibration services cover inspection tools such as gages, micrometers, sine bars, calipers, and dial indicators to evaluate and improve equipment performance. - Assembly

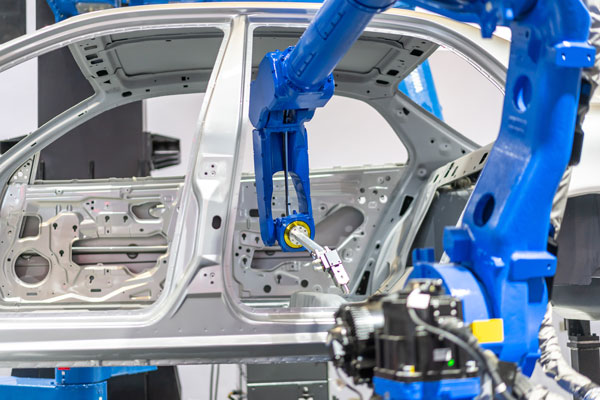

Assembly of robotics employs a variety of techniques such as welding, soldering, adhesive bonding, and mechanical fastening. Many of these assembly tools require regular calibration for safety and accuracy. For torque tool applications, we have a specialized nationwide network of labs that sell, calibrate, and repair torque tools.

Testing and Quality Assurance

Once the robot is assembled and programmed, it undergoes rigorous testing to ensure that it meets performance specifications and safety standards. Testing may include functional testing, stress testing, accuracy verification, and calibration.

- Dimensional

Robotic joints, kinematics and end effectors or Tool Center Points (TCP) are run through motion verification tests to validate the accuracy and repeatability of the robot's movements. To effectively compare the actual positions with the expected positions, make sure your dimensional tools are regularly calibrated with Transcat Dimensional Calibration Services. - Electrical

Wiring harnesses, power distribution systems, circuit boards, sensors, actuators, and control systems are just some of the electronic subsystems critical to the function of an industrial robot.

Transcat Electrical Calibration Services supports a comprehensive range of meters and testers including the calibration of multimeters, sensors, power supplies, and transmitters.

Installation and Support

The robotics manufacturers' job does not end with the shipment of the robotic systems. They most often play a critical role in the installation, commissioning, and lifecycle support of the robots adding to their testing processes.

- Installation and testing

Configuring the robot for its specific environment and application includes calibrating sensors and actuators, programming motion trajectories, and conducting initial tests to ensure proper operation. Many of these tests mirror the ones done during the manufacturing of the robots, requiring the test instruments to be similarly calibrated for comparable results after installation. - Support

Industrial robots require regular maintenance and recalibration to ensure that the robot continues to operate accurately over time. Environmental factors, wear and tear, and component degradation can all affect the performance and safety of the robot. Again, the comparability of test results is important to the efficiency of the maintenance program and the accuracy of the recalibration.

Featured Transcat Solutions for Robotics Manufacturing

Accredited Calibration Labs

Our labs have the broadest calibration capabilities in the industry including 6 fully equipped, ISO 17025-accredited, torque standard calibration labs in North America. We are also factory-authorized to Stahlwille torque standards.

Metrology Expertise

A majority of Transcat’s calibration management staff have been trained by the US Military in the Precision Measurement Equipment Laboratory (PMEL) processes. Count on our experts in metrology to manage your calibrations to robotics industry guidelines such as ISO 10218 and ANSI/RIA R15.06.

Tool Calibration Service Types

Our flexibility in service delivery means greater efficiency and less disruption to your business and processes. You can rely on Transcat to provide precise, reliable, and fast calibration service – in our lab or at your facility. Find the service option that best fits your needs.

Test & Measurement Instruments

We offer a wide range of types and brands of test & measurement Instruments to maintain the productivity, accuracy, and compliance of your robotic systems from initial quality testing through lifecycle support. We are your one-stop shop to buy, rent, and obtain expert calibration.

For more information about our accredited calibration services for industrial robotics manufacturing and customer installation applications, call one of our calibration professionals at 800-828-1470 or contact us.