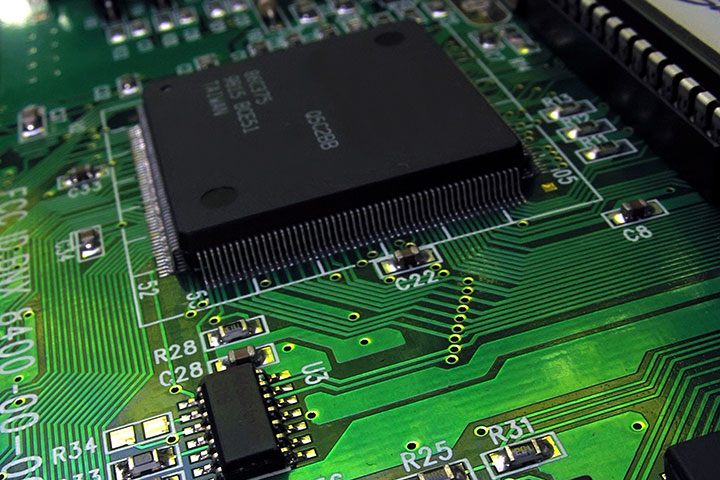

Electronics Manufacturing Calibration Services

In the highly competitive industry of electronics manufacturing, tight process controls are necessary to ensure the quality, reliability, and performance of their products while meeting regulatory standards.

Adopting quality management systems such as ISO 9001, ISO 14001, and IPC-A-610 enables manufacturers to comply with legal and regulatory compliance requirements including the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations.

Transcat offers accredited services to support detailed calibration procedures and documentation across a wide range of test and measurement instruments for maintaining traceability and compliance with quality standards.